RES

Concentrated solar power test bench

The test station designed replicates a prototype for the chemical looping investigation and synthetic gas production. The reduction reaction of MeOx is investigated considering the receiver designed for higher temperature, the test-rig is equipped with a paramagnetic oxygen sensor to detect the oxygen released from the reduction reaction. It is mainly investigated the thermal reduction reaction, with the possibility to employ also methane, from gas cylinders contained in an external cabinet, for the assisted reduction reaction. Three N-type thermocouples are installed externally to the receiver, while one B type thermocouple is installed inside the cylinder bed which allow to study the temperature distribution.

Wind test bench

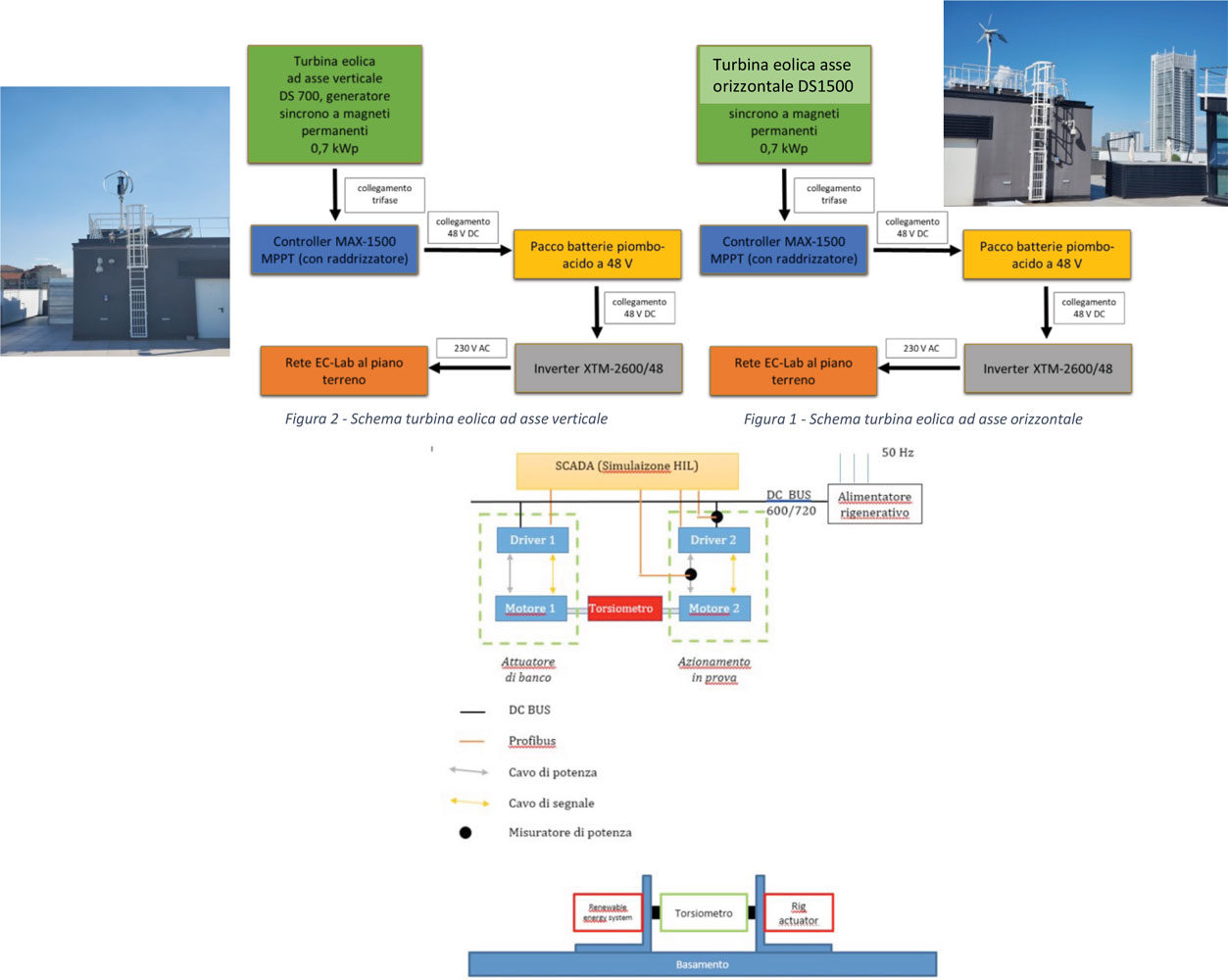

The wind test bench is devoted to micro and mini wind turbines. The overall bench, connected to the Hardware in the loop, is made of the following infrastructures:

- A 0.7 kW vertical axis micro wind turbine (Darrieus-Savonius blades, with low cut-in speed).

- A 1.5 kW horizontal axis micro wind turbine.

- An anemometer.

- A 50 kW PTO (Power Take Off) test bench for mini wind electric generators testing.

The two turbines are installed on the roof of the Energy Center building: this ensures them the possibility to exploit major winds and local breezes. An anemometer is installed in order to monitor the wind turbines' performances and study the effects of surrounding buildings on the wind profile.

The PTO test bench is installed on the ground floor of the Energy Center building; it consists of a 50 kW electric motor and a tensiometer for analyzing the performances of tested generators.

Geothermal test bench

The geothermal test bench focuses on earth-contact walls of buildings used as heat exchangers for heating and cooling purposes.

The test bench is made up of:

- An adjustable-power geothermal loop: the exchanger is a prototype of an innovative modular energy geostructure embedded in the ground. Three different modules that can be deployed in different ways give adjustable power capacity;

- A simulated thermal user: the installation is equipped with a fan coil that can simulate heat or cooling loads. A 100-litre capacity puffer provides the additional thermal capacity to the system;

- A small scale reversible glycol-to-glycol heat pump;

- A large monitoring system to investigate system thermal performances, ground thermal and hygrometric effects and structural effects on the energy geostructure.