CO2 electrochemical reduction and H2

CO2 electrochemical reduction and H2

Low-temperature electrolysis

Electrochemical test station

The electrochemical test station is designed to characterize and evaluate the performance and stability of electrolyzer cells and short stacks. The system is able to operate under pressurized conditions, up to 28 bar. Water exiting the electrolyzer is sent to the gas separators and then recirculated back to the electrolyzer inlet by means of a pump. The system is highly flexible: 2 pumps with different size have been installed to allow the operation of both single cells and short stacks. A mixed bed ion exchanger is also present for the cleaning of water. The functionality of the resin is very important in commercial PEM water electrolyzers, as highly purified water is required to minimize metallic cation impurities, thus avoiding loss of performance of the electrolyzer. Water conductivity is continuously monitored through a conductivity sensor located on the recirculated circuit. A heat exchanger for cooling purposes and an electric heater are also present for the electrolyser thermal management by acting on the temperature of the recirculated water flow

Cell housing

The cell housing is composed of the anodic and cathodic bipolar plates, which are made of Titanium to be resistant to corrosion. They present flow fields with specific channel geometry to allow water entering the electrolyzer and to enhance the thermal management. Porous transport layers and the Catalyst Coated Membrane (CCM) are placed between the two bipolar plates.

Potentiostat/galvanostat

EnergyLab XM is an application specific XM instrument designed to perform electrochemical measurements. EnergyLab XM includes a reference grade potentiostat, frequency response analyser and 2A booster. The unit may be operated in boosted or unboosted mode (with automatic switching), providing optimum test conditions and accuracy for a wide range of energy devices. This device is suitable to perform Electrochemical Impedance Spectroscopy (EIS) and Cyclic Voltammetry (CV) tests on both single cells and short stacks.

High-temperature Electrolysis (SOEC)

Test Bench

Cell housing

The test-fixture is a metallic housing where square SOECs are placed. Metallic grids between the housing and cell electrodes enhance the electrical contact with electrodes and ensures and even current distribution. The test-fixture ensures gas and steam distribution to the cell and the connection to an electronic load for the characterization (current wires connected to the two metallic base). Sensing wires (Pt wires) are connected to the metallic grids to act as voltage probes. Mica seals and weight-based compression system ensures the cell sealing.

Electronic load

The bench is equipped with an electronic load (PLZ 664, Kikusui) for current-voltage characterization of cells and short stacks. The current is generated in the circuit with a DC power supply (SM 30-100, Delta Elektronica). Constant current, constant voltage, constant power modes are available to perform customizable characterizations. The electronic load can also perform also AC impedance measurements using a Gamry impedance analyzer (FC 350, Gamry Instruments) connected to the load to modulate the current.

Photo-electrochemical CO₂ reduction to chemicals and fuels

Modular Photo/Electrocatalytic Test-Benches

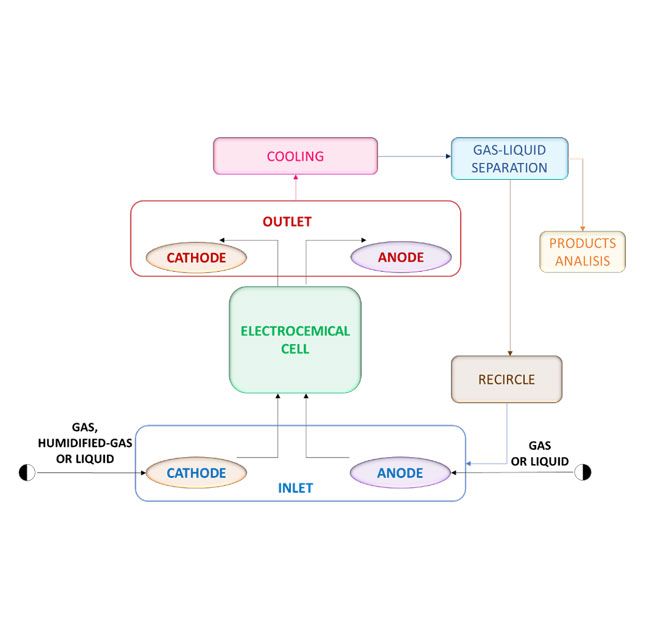

Two test-benches are available to perform photo-electrocatalytic and electrocatalytic tests for valorising of gaseous (i.e. CO2) or liquid (e.g. wastewater, industrial by-products) waste streams and producing high added value products (fuels o chemicals). A broad range of operative conditions can be employed to feed the anode and cathode of the electrochemical cell (pressure from 1 to 30 bar; temperature from 20 to 150 oC; pH from 1 to 14). The cathode inlet can be set to feed a gas, humidified gas or liquid stream, for performing CO2 electroreduction tests in gas-phase or with CO2 dissolved in the liquid electrolyte. The storage tanks capacity and the recirculation system allow to simulate continuous operation for tests from TRL3 to TRL4/5. An automatized control system ensure the monitoring, control and datalog of the process parameters (P, T, flow rates, etc) during the tests, thanks to the use of Bronkhorst thermal mass flow controllers for gases (EL-FLOW SELECT), Coriolis mass flow controllers for liquids (mini CORI-FLOW), digital electronic pressure meters (EL-PRESS) and controlled evaporation and mixing (CEM-System) for humified-gas feeding as well as by Sepachrom dual piston HPLC pumps.

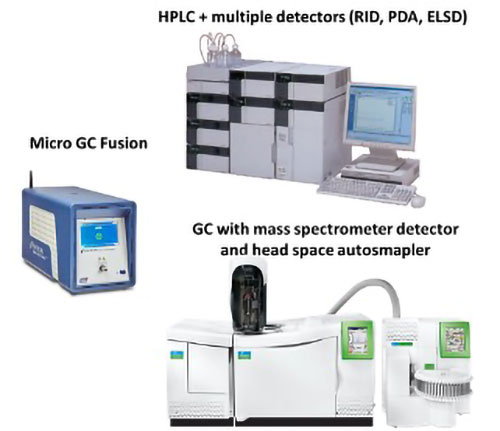

Liquid/Gas Analysers

Two test-benches are available to perform photo-electrocatalytic and electrocatalytic tests for valorising of gaseous (i.e. CO2) or liquid (e.g. wastewater, industrial by-products) waste streams and producing high added value products (fuels o chemicals). A broad range of operative conditions can be employed to feed the anode and cathode of the electrochemical cell (pressure from 1 to 30 bar; temperature from 20 to 150 oC; pH from 1 to 14). The cathode inlet can be set to feed a gas, humidified gas or liquid stream, for performing CO2 electroreduction tests in gas-phase or with CO2 dissolved in the liquid electrolyte. The storage tanks capacity and the recirculation system allow to simulate continuous operation for tests from TRL3 to TRL4/5. An automatized control system ensure the monitoring, control and datalog of the process parameters (P, T, flow rates, etc) during the tests, thanks to the use of Bronkhorst thermal mass flow controllers for gases (EL-FLOW SELECT), Coriolis mass flow controllers for liquids (mini CORI-FLOW), digital electronic pressure meters (EL-PRESS) and controlled evaporation and mixing (CEM-System) for humified-gas feeding as well as by Sepachrom dual piston HPLC pumps.

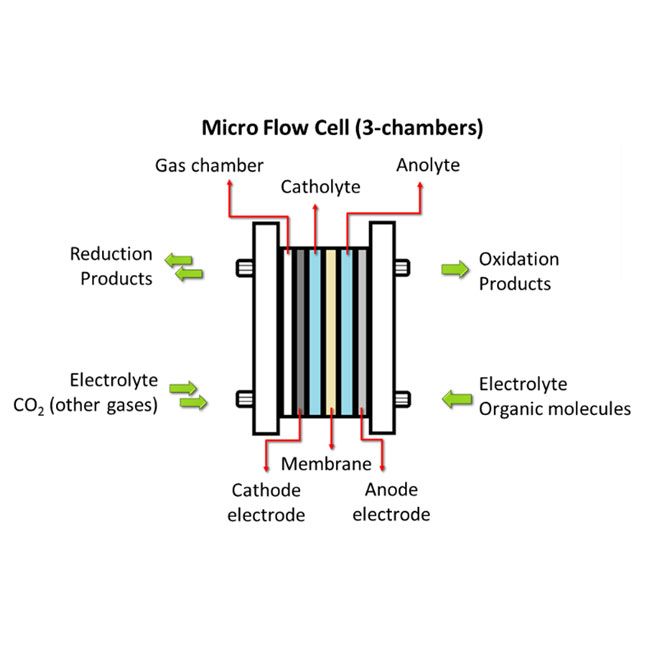

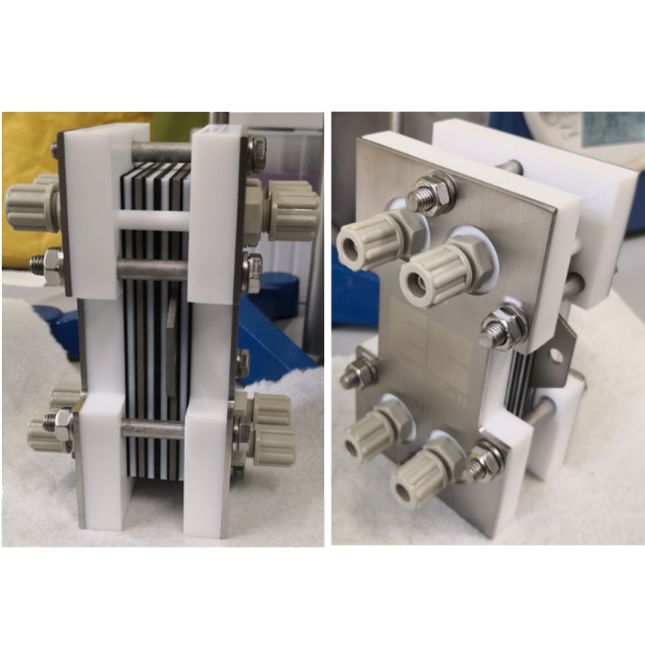

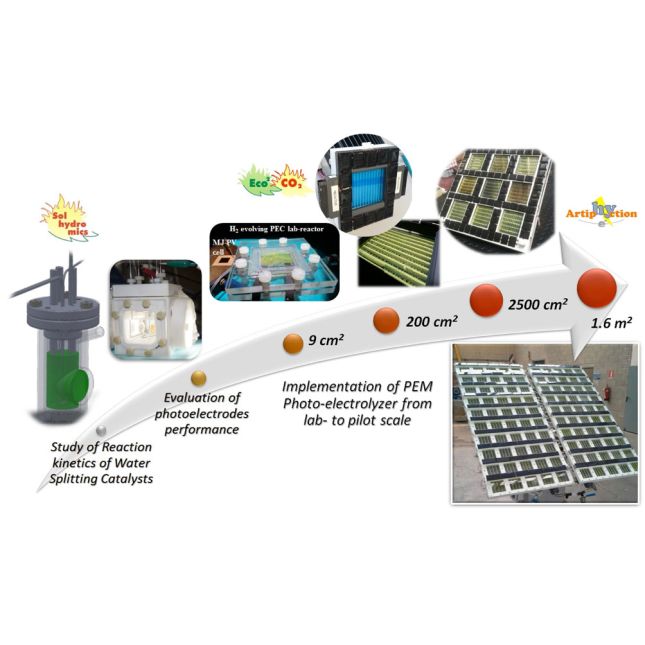

Photo/electrochemical cells

Photo/electrochemical cells and reactors with different design and active area are available to perform water splitting for H2 production and electrochemical CO2 conversion reactions in gas and liquid phase at different scales (electrode areas from 1 cm2 up to 100 cm2). There is a broad expertise in the design and scale-up of photocatalytic and photo/electrochemical technologies.

UV-lamps and Sun-simulators

UV and Visible lamps with sun simulated spectra are available to perform photoelectrochemical tests of devices with illuminated areas from few cm2 up to 30 x 30 cm2. For instance: Xe Arc Lamp (Oriel Newport) with AM 1.5G filter and IR-water filter, Solar simulator class A (area 30 x 30 cm2) by LUMIX and SOLARONIX, among others.

Microactivity Effi reactor system for thermocatalytic tests

The Microactivity Effi reactor system is a modular laboratory system for measurement of catalytic activity and for the study of the yield, kinetics and stability of different catalytic reaction systems. It has a broad range of operative conditions, being able to perform redox cycles from ambient conditions up to 800 oC and 40 bar. It is equipped with cutting-edge process control technology that enables to program a series of experiments from the computer, even on the network, and obtain real-time results with a high degree of reproducibility and accuracy.

Electrochemical CO2 reduction to added value chemicals

Modular Photo/Electrocatalytic Test-Benches

Two test-benches are available to perform photo-electrocatalytic and electrocatalytic tests for valorising of gaseous (i.e. CO2) or liquid (e.g. wastewater, industrial by-products) waste streams and producing high added value products (fuels o chemicals). A broad range of operative conditions can be employed to feed the anode and cathode of the electrochemical cell (pressure from 1 to 30 bar; temperature from 20 to 150 oC; pH from 1 to 14). The cathode inlet can be set to feed a gas, humidified gas or liquid stream, for performing CO2 electroreduction tests in gas-phase or with CO2 dissolved in the liquid electrolyte. The storage tanks capacity and the recirculation system allow to simulate continuous operation for tests from TRL3 to TRL4/5. An automatized control system ensure the monitoring, control and datalog of the process parameters (P, T, flow rates, etc) during the tests, thanks to the use of Bronkhorst thermal mass flow controllers for gases (EL-FLOW SELECT), Coriolis mass flow controllers for liquids (mini CORI-FLOW), digital electronic pressure meters (EL-PRESS) and controlled evaporation and mixing (CEM-System) for humified-gas feeding as well as by Sepachrom dual piston HPLC pumps.