CO2 electrochemical reduction and H2

In this macro-area, the facilities and laboratories to develop and test (photo)electrocatalysts for CO2 conversion to chemicals and fuels, as well as the facilities and laboratories for H2 production that are available within the CCL infrastructure are presented. In addition, testing facilities for electrolysis, at low-temperature and up to 30 bar for cells/stacks, and at high-temperature for cells testing at ambient pressure, are also included.

Laboratories within the infrastructure

Electrochemical CO₂ reduction to added-value chemicals and fuels

Characterization bench for the electrochemical reduction of CO₂ from the lab-scale up to a pre-prototyping level from ambient conditions to 150 °C and 10 bar.

In situ TEM Lab

Experimental set-up for the in-situ electrochemical characterizations to observe, through TEM, the evolution of the structural, compositional and morphological properties of the catalyst (that could cause variations in the catalyst activity and selectivity) while cycling at the same electrochemical conditions operated ex-situ.

Photo/electrochemical CO₂ reduction to chemicals and fuels

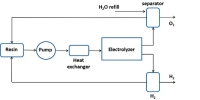

Low-Temperature Electrolysis

The electrochemical test station will be used to carry out tests on both single cells and stacks, investigating the hydrogen production by water electrolysis. The test station was designed to work with different low temperature electrolysis technologies: proton-exchange membrane (PEM) and alkaline devices. The electrolyzer performance will be analysed at different operating conditions (current density, temperature and pressure). Durability tests can be also performed to study how the performance degrades over time.

High-temperature Electrolysis (SOEC)

The test bench is designed for the electrochemical testing of Solid Oxide Electrolysis Cells at ambient pressure. The cells are placed in an electrically heated test-fixture that ensures gas and steam distribution to the cell and the connection to an electronic load for the characterization (current-voltage, impedance measurements). The test-bench is equipped with a remote control system.