Ionic liquids for CO2 capture

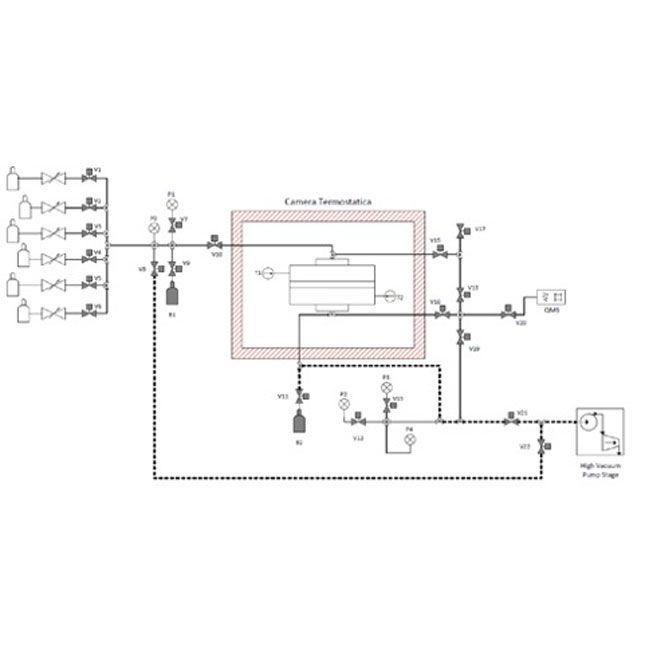

The test station design replicates a traditional two-column scheme for the removal of CO₂ from different gas mixtures (N₂, O₂/H₂, CH₄, CO). The rig allows the execution of tests in two modes.

Aqueous solutions of monoethanolamine are tested as benchmark solvents. Chemisorption through bio-inspired ionic liquids that rely on choline and amino-acids dissolved in dimethyl sulfoxide (DMSO) is tested as an alternative to common amine-scrubbing. The measured data will be useful to tune and adjust the model that simulates carbon capture, taking into account the transport phenomena. This research route embraces the brand-new approach of carbon reuse, supporting CO₂ combination with a versatile platform molecule like H2, to replace existing unsustainable processes and integrate Power-to-X schemes for the short- and long-term storage of excess energy and its differentiation in multiple value-added vectors.

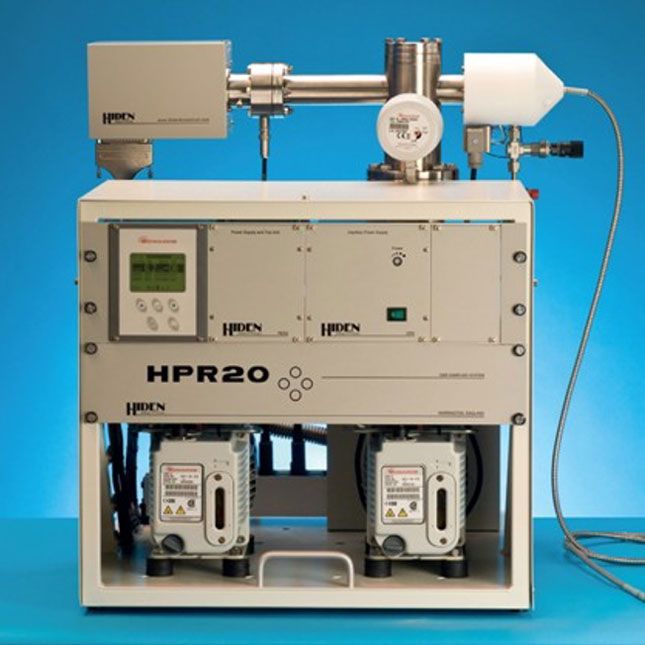

A Hiden HPR-20 QIC mass spectrometer (MS) is installed in the laboratory. The MS is configured for continuous analysis of gases and vapours at pressures near the atmosphere. Operating to 200 °C, the QIC (quartz inert capillary) flexible 2 m capillary inlet provides fast response times of less than 300 ms. The HPR-20 QIC R&D system has a mass range of 200 AMU and a detection capability from 100 %vol. to less than 5 ppbv. Unique to Hiden gas analysis systems, soft ionisation allows users to selectively ionise different gases by setting the ionisation energy for a particular mass. This powerful technique is used to analyse and to detect, for example, compounds with the same mass, such as CO and N2 (28 g/mol).

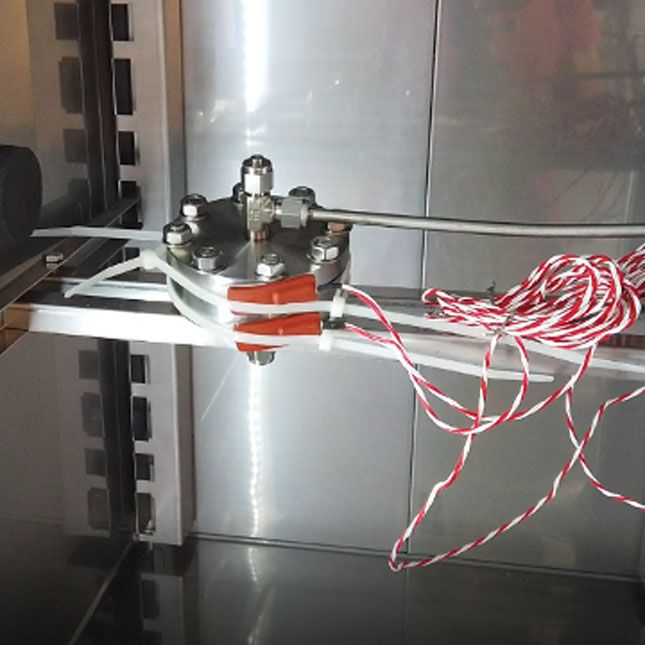

Experimental setup used to characterize membranes

Membrane housing in the thermostatic chamber. The feed mixture of gas flows from the top of the membrane while the permeate is collected from the downside

Thermostatic chamber with temperature ranging from -20 to 70°C

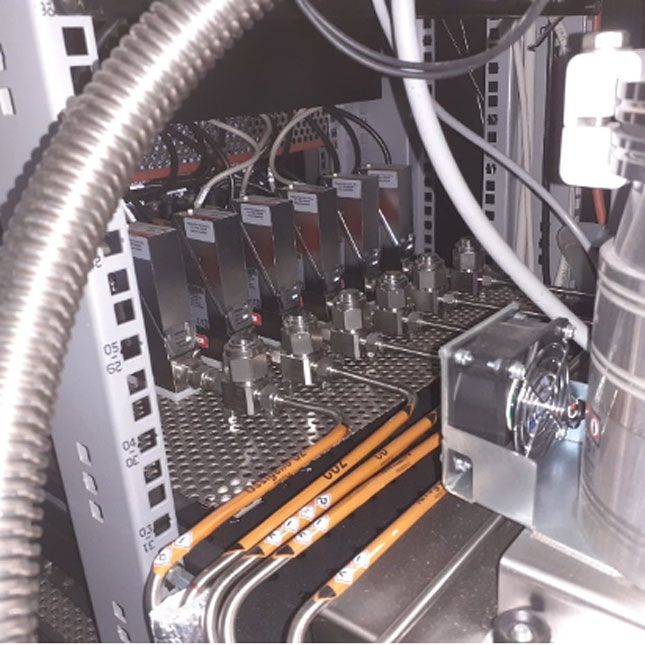

Six mass flow controllers

Test station unit. On the top there is the computer control while the vacuum pump is visible at the bottom

Mass spectrometer available in the laboratory

Membranes for CO2 capture

Membrane separation is a process used to treat a mixture of gas and separate part of them. The main goal of this testation is removing the CO2 from simulated flue gas, biogenous gas mixture such as biogas or an SNG stream. The two main mass transport properties (i.e., permeance and selectivity) of a generic membrane can be measured with temperature ranging from -20 to 80 °C, while the pressure can range between 1 and 30 bar, for both single gases and gas mixtures. The membrane can be supplied with a mixture of CO2, CH4, CO, H2, N2 and O2. The use of other gas mixtures is possible by having calibrated, gas cylinders to be used aside test facility. The fixed volume/pressure decay experimental apparatus to measure the mass transport properties of the tested membranes is schematically illustrated in Figure 4.

The facility is provided by two different membrane housings shown in figure 5, which allow an effective membrane area of 28.30 cm2 and 7.0 cm2, respectively. The membrane module is housed into a climatic chamber able to keep a constant temperature (see figure 6). Up to six mass flow controllers supply the buffer line B1, with a fixed feed volume of 1 litre, and the range allowed is between 0 and 100 -Nml/min for each gas. The six mass flow controllers are illustrated in figure 7. Currently, a feed pressure up to 30 bar can be reached due to limited pressure on the inlet gas side. On the other hand, the permeate pressure is measured in the range of 0-10 bar. A new pressure sensor with a higher resolution and lower range is installed. The mass flow controller section, the temperature of the climatic chamber and all the valves are computer-controlled as illustrated in Figure 8.

At the first step, the membrane cell and all the fixed permeate volume were evacuated with a turbo-pump, which grants the removal of both gases and vapours inside the pipes.

Once the vacuum procedure has been completed, the storage B1 can be filled with the desired gas mixture until the operating pressure is reached. The mass flow and composition of the permeate gas mixture can be measured at the outlet of the valve V20 by a spectrometer and a flow meter.

A Hiden HPR-20 QIC mass spectrometer (MS) is installed in the laboratory. The MS is configured for continuous analysis of gases and vapours at pressures near the atmosphere. Operating to 200 °C, the QIC (quartz inert capillary) flexible 2 m capillary inlet provides fast response times of less than 300 ms. The HPR-20 QIC R&D system has a mass range of 200 AMU and a detection capability from 100 %vol. to less than 5 ppbv. Unique to Hiden gas analysis systems, soft ionisation allows users to selectively ionise different gases by setting the ionisation energy for a particular mass. This powerful technique is used to analyse and to detect, for example, compounds with the same mass, such as CO and N2 (28 g/mol).