CO2 thermochemical reduction

In this macro-area, the facilities for the thermocatalytic conversion of CO₂ to chemicals or fuels that are available within the CCL infrastructure are presented. Testing facilities with batch and continuous reactors of different scales are available. The benches perform automatic redox cycles from ambient condition up to 800°C/1800°C and 40 bar, and are equipped with analytical instruments for kinetics, yield and stability studies of catalytic systems and oxygen carrier materials.

Laboratories within the infrastructure

Micro-reactor test bench for chemical looping cycles

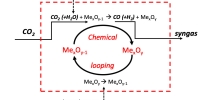

Experimental set-up designed to test powder/pellet materials in micro-reactor for the elaboration of kinetic studies on the thermochemical reduction of CO₂ and H₂O through the analysis of reaction products. The bench allows to perform user-customized fully automatic redox cycles with imposed gas mixtures and controlled humidity in a wide range of temperatures (up to 1800 °C).

Test bench for thermochemical CO₂ hydrogenation to fuels

The test bench was designed to test catalytic materials (powder or pellets) in a fixed-bed reactor for producing synthetic fuels (i.e., methane, methanol, dimethyl-ether and hydrocarbons) via thermochemical CO2 hydrogenation. The test bench can operate in a wide temperature range (RT – 550 °C) and pressure (1 – 30 bar) by using CO2, CO, H2, CH4 and N2. The analytical setup consists in an on-line Emerson X-Stream gas analyser and an Agilent Technologies 7890B gas-chromatograph equipped with a thermal conductivity detector (TCD) and a flame ionization detector (FID). The test bench is suitable for investigating catalytic performances in terms of activity and stability or performing kinetic studies.