Services

CO₂ capture

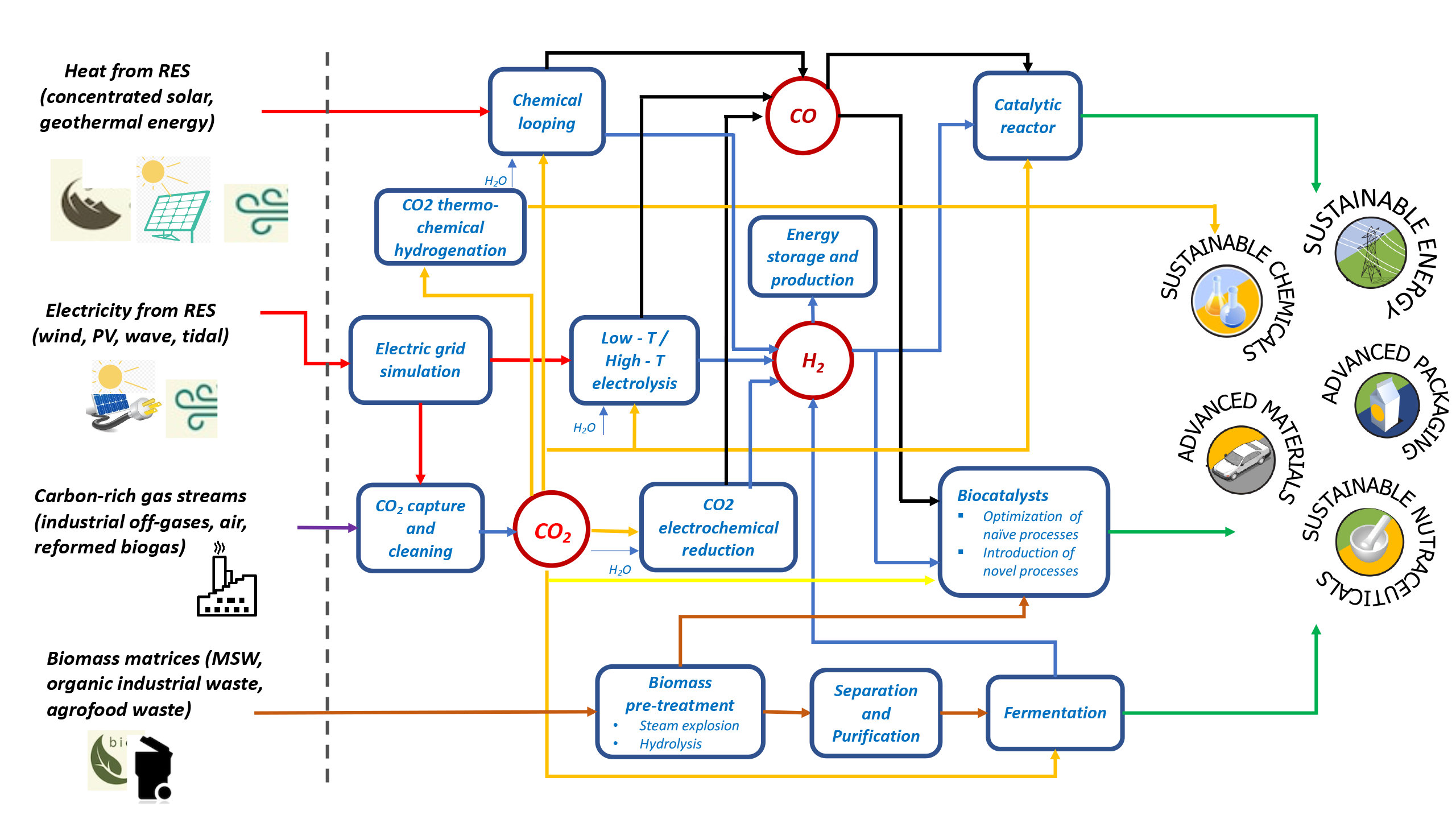

CO₂ Circle Lab tests CO2 recovery from the gas streams of industrial processes (e.g. refineries, cement, iron & steel production, natural gas processing, hydrogen production), power plants and biogas plants, and in future perspectives also from air (Direct Air Capture).

Services of the test bench for CO2 capture, with traditional (e.g., amine-based aqueous solutions) and innovative (e.g., ionic liquids) solvents, include:

- testing at prototypal level the main properties of the solvents (e.g., saturation, time for complete ab-/desorption, selectivity);

- testing of the efficiency of liquid solvents;

- comparison of energy requirements for range of solvents;

- analysis on solvent degradation;

- optimize working conditions;

- tune and validate simulation models.

Services of the test bench for CO2 separation via membrane process include:

- Membrane characterization (e.g. solubility, diffusivity, permeability, gas selectivity);

- Analysis of membrane degradation in case of wet gas;

- Analysis of membrane degradation, calendar ageing and or cycle ageing;

- Optimal working conditions;

- Tuning and validation of complex models with experimental data.

CO2 electrochemical reduction and H2

Revenue streams for Power-to-Hydrogen range from supplying hydrogen to industry and transport applications to providing electricity grid services and injecting hydrogen into the gas grid.

CO2 Circle Lab low-temperature electrochemical test stations aim at:

- Testing the performance of low-T electrolysis cells and short stacks under different operating conditions (temperature, pressure, current, water flow rate)

- Performing durability tests to investigate stability issues of electrolysis

- Producing high purified hydrogen and oxygen

Several value streams for Power-to-Hydrogen are envisaged from selling hydrogen to industry and transport applications, to providing electricity grid services and injecting hydrogen into the gas grid.

CO2 Circle Lab high-temperature electrochemical test station aims at:

- Testing the performance of SOEC cells (and short stacks) under different operating conditions (temperature, current, gas composition)

- Performing durability tests to investigate stability issues of electrolysis

- Producing hydrogen and oxygen

CO2 Circle Lab enables several approaches for the conversion of waste streams (CO2 or organics in wastewater from industrial processes) to useful products, in a circular economy perspective, by exploiting renewable energy sources - water and sunlight or renewably produced H2. In this context, the modular (photo-)electrocatalytic test benches are aimed to:

- Testing the performance of mid- &low-T co-electrolysis cells for conversion of CO2 to chemicals and fuels coupled to water electrolysis for O2 production or advanced oxidation processes for: wastewater mineralisation or conversion of organic residuals to useful products.

- Benchmarking and testing of new catalysts materials under different operating conditions (temperature, pressure, current density, potential, flow rate)

- Performing durability tests to investigate stability issues of photo/electrocatalysts

- Developing new technologies for producing high-value products from wastes and exploiting renewable energy.

The availability of the microactivity Effi reactor system affords::

- Benchmarking and testing the performance of catalytic systems in terms of yield, selectivity and stability for the conversion of CO2 (or other gaseous waste streams) to high added value products (e.g. methanol, dimethylether, and others) by means of hydrogenation or other catalytic reactions;

- Process optimization of operative conditions (e.g. temperature, pressure, velocity);

- Data acquisition for kinetics modelling, scaled-up process simulation, techno-economic analyses and environmental studies.

The in situ TEM affords the observation of the evolution of the catalyst while cycling at the same electrochemical conditions operated ex-situ.

Bioenergy

CO2 Circle Lab allows to test and validate a wide variety of processes and uses for the valorisation of organic products / by-products with various purposes, as for example, energy production, through anaerobic fermentation, and extraction of compounds with high added value.

The services offered by the area can be detailed as follows:

- Optimisation of the process and pre-treatment of organic matrices to improve the extraction and purification yield of substances of interest for green chemistry such as sugars, lipids, antioxidants, solvents and biostimulants;

- Agri-food by-products and organic wastes anaerobic fermentation and evaluation of the energy production potential;

- Tests on outdoor photobioreactors for the cultivation and enhancement of microalgae.

CO₂ thermochemical reduction

Several value streams for the conversion of waste streams (CO2 or organics in wastewater from industrial processes) to useful products can be outlined, in a circular economy approach, by exploiting renewable energy sources (like water and sunlight or renewably produced H2).

The modular photo/electrocatalytic test benches are aimed at:

- Testing the performance of mid- &low-T co-electrolysis cells for conversion of CO2 to chemicals and fuels coupled to water electrolysis for O2 production or advanced oxidation processes for: wastewater mineralisation or conversion of organic residuals to useful products;

- Benchmarking and testing of new catalysts materials under different operating conditions (temperature, pressure, current density, potential, flow rate);

- Performing durability tests to investigate stability issues of photo/electrocatalysts;

- Developing new technologies for producing high-value products from wastes and exploiting renewable energy.

The Microactivity Effi reactor system is aimed at:

- Benchmarking and testing the performance of catalytic systems in terms of yield, selectivity and stability for the conversion of CO2 (or other gaseous waste streams) to high added value products (e.g. methanol, dimethylether, and others) by means of hydrogenation or other catalytic reactions;

- Process optimization to find the best operative conditions (temperature, pressure, velocity, etc);

- Data acquisition for kinetics modelling, scaled-up process simulation, techno-economical analyses and environmental studies.

RES

The CO₂ Circle Lab test benches allow to study, to simulate and to validate models considering several aspects related to the RES: wind solar and geothermal sources. The main services could be summarized as follows:

- Testing of glycol-to-glycol heat pumps developed for single dwellings and small-scale users;

- Testing the thermal reduction of MeOx in a chemical looping process for the SNG production;

- Investigating on the receiver geometry for the energy production considering Stirling engines, ORC and Rankine systems, etc.;

- Investigating on the micro and mini turbine wind generation in urban areas;

- Testing wind generators for energy production through a PTO test bench equipped with a tensiometer.

Multi-energy systems analysis

Thanks to the laboratory equipment it is possible to study the behavior of hardware devices and equipment, management and control systems, protection systems, inserted with (power) hardware in the loop mode in the simulated working environment. It is also possible to study the impact of such devices on the power grid.

The services proposed are:

- Testing of electrical equipment in HIL and PHIL configuration, with possible recipients: device manufacturers, TSOs, DSOs, multi-utilities, producers, consumer associations;

- Training of operators, with possible recipients: DSOs, TSOs, private subjects;

- Didactics for external organizations, with possible recipients: public and private electrical operators.

Bioconversion of C1 gas streams into commodities

CO2 Circle Lab brings green biotech solutions for carbon recycling to market. The secret is microorganisms that turn the carbon in industrial exhaust gas into revenue products. The biotechnological solutions proposed include:

- Biobased production of business-to-business molecules valuable in green chemistry applications by exploiting the metabolic capabilities of photosynthetic organisms and curating the design, assembly and operation of the bioprocesses in market-oriented photobioreactors.

Currently targeted markets include packaging, flavouring, cosmetics and personal care. - Development of gas fermentation processes based on the metabolic features distinctive of acetogenic bacteria. This technology suitably integrates in cleantech processes for the production of biomolecules (mainly diols, alcohols, acids) for diverse applications, for instance in the energy, chemistry, and packaging sectors, starting from industrial waste streams and synthetic gas mixtures (hydrogen, carbon monoxide and carbon dioxide).

- Development of novel solutions in the energetic sector exploiting the metabolic potential of hydrogenotrophic methanogenic archaea, which are able to use H2 for the reduction of CO2 to produce biological methane, as well as of aerobic methanotrophs and archaeal methanotrophs to develop chemical intermediates.

Energy storage

CO2 Circle Lab emploies nanostructured materials and nanotechnologies in the fabrication of laboratory prototypes for energy harvesting and storage devices, also in flexible, wire-shaped or floating architectures for advanced and innovative applications. The principal subjects under development are: supercapacitors and hybrid devices for energy harvesting and storage. CO2 Circle Lab develops also solutions to integrate the previous prototypes with CO2 electro-reduction reactors.

CO2 Circle Lab enables the complete characterization of pre-industrial cells, modules and battery packs. The testing carried out consist in:

- Performing tests (cycleability, cycling life)

- Aging tests:

- Calendar aging

- Cycle aging

Calendar aging is influenced by the storage parameters, namely the temperature and the state of charge (SOC). The degradation during cycle aging depends on the operating parameters: temperature, state of charge (SOC), current amplitude and depth of discharge (DOD). For both, calendar and cycle aging, aging mechanisms are usually investigated by alternating electrochemical characterizations at a reference condition with storage or cycling periods at predefined conditions.

- Abuse safety tests: the scope of the abuse test is to evaluate the compliance to main safety standards applicable to automotive batteries: thermal runaway, over-charge/discharge, nail test, crush test.

Synthesis and Characterization

CO₂ Circle Lab offers the following services:

- Characterization of minerals for CO2 capture;

- Recovery of industrial minerals and / or essential raw materials (CRM) from old mining sites or mineral dumps;

- Recovery of critical raw materials (CRM) from PCBs of electrical and electronic equipment;

- Characterization of plastics and microplastics;

- Characterization of the components of airborne particulate for the identification of emission sources;

- Development and synthesis of new heterogeneous catalysts, photocatalysts and electrocatalysts for sustainable processes;

- Physical-chemical deposition and growth of nanomaterials;

- Consilience for scale-up of synthesis approaches.